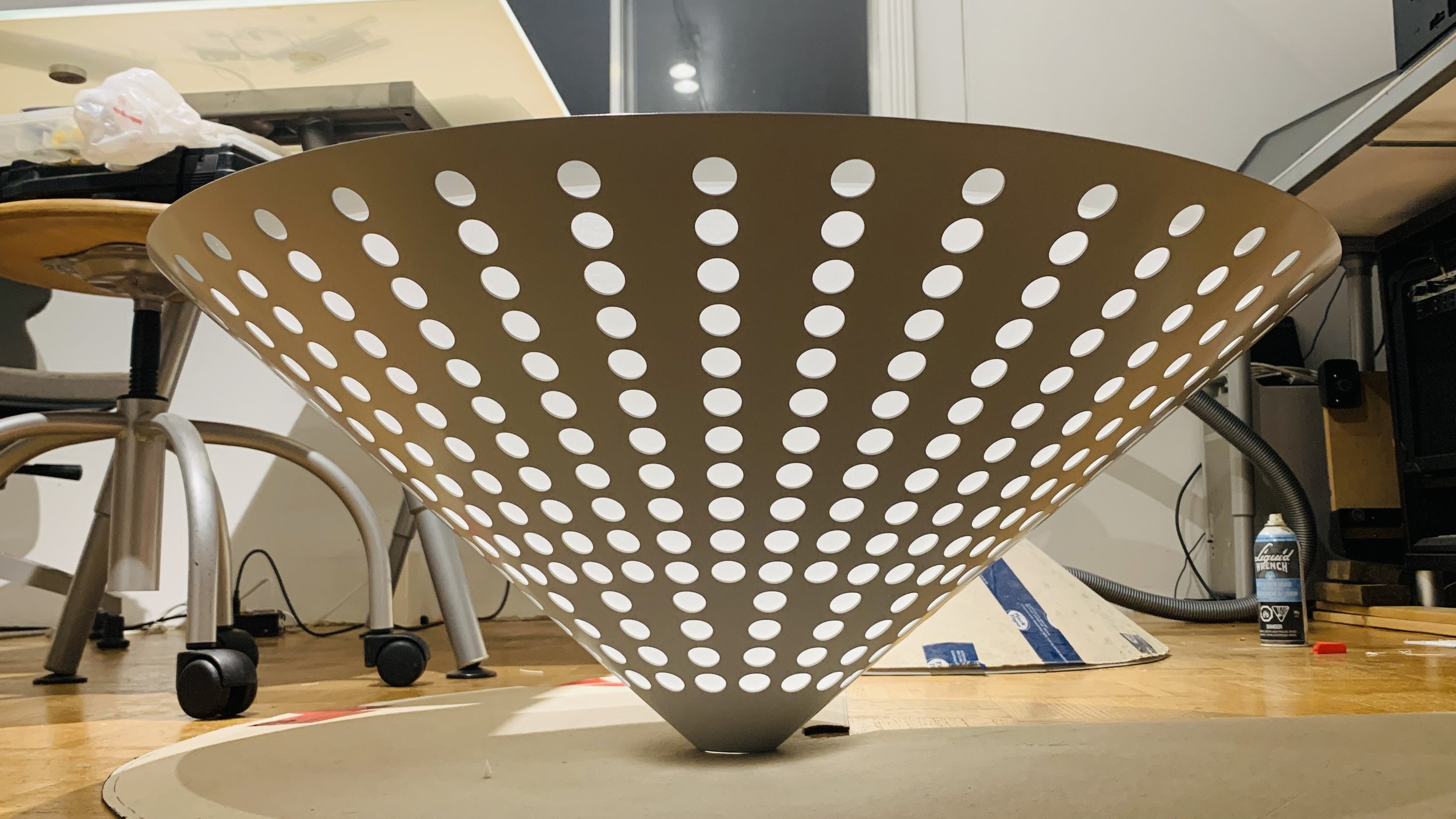

The cone light, commissioned for Montana Labelle Design, is a unique and captivating lighting fixture that combines meticulous craftsmanship with elegant aesthetics. This design description provides an overview of the key features and manufacturing processes involved in creating this stunning piece.

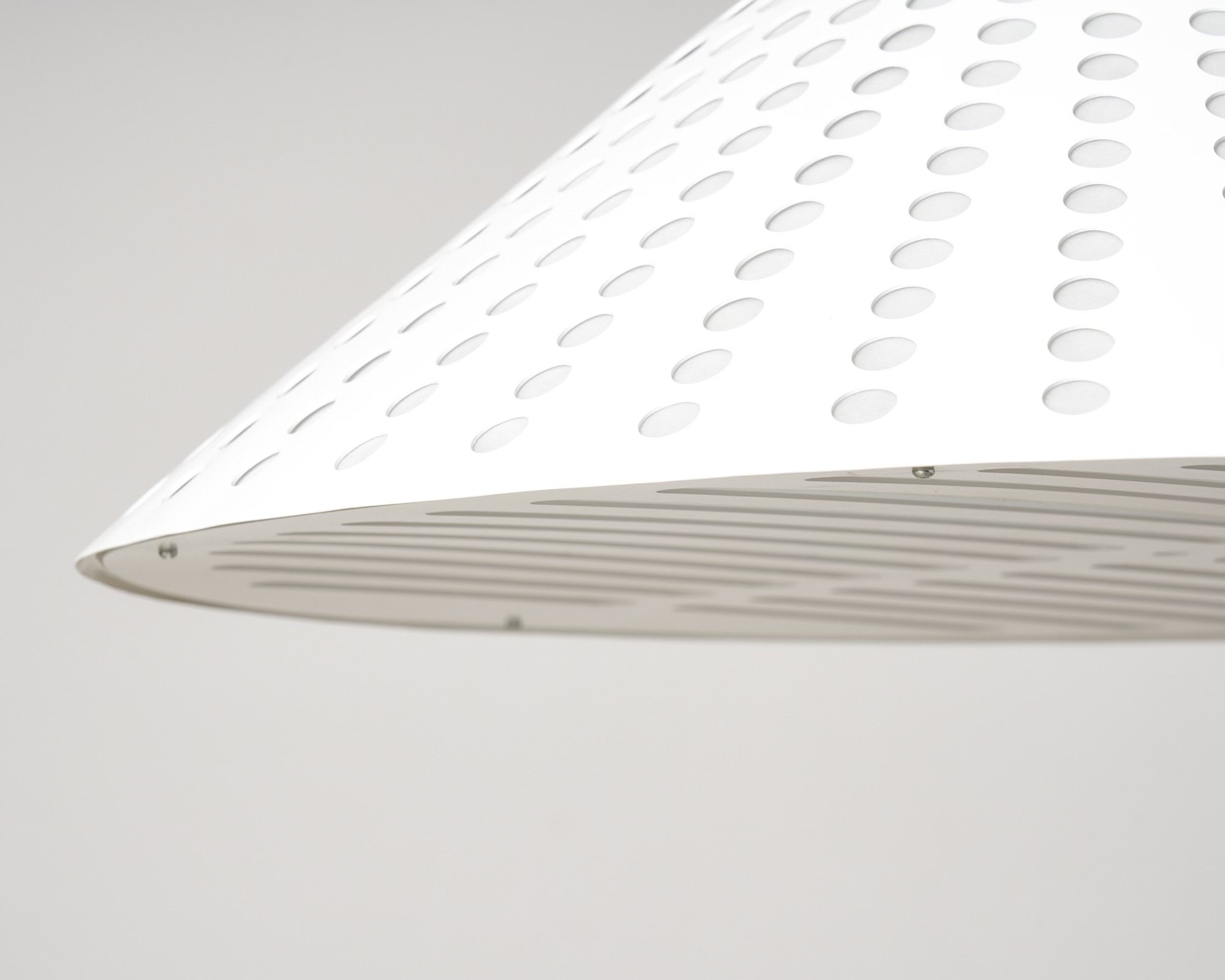

The pendant light features a cone-shaped design, which adds a touch of sophistication to any interior space. It is meticulously laser cut from 1/16 inch thick steel, ensuring durability and precision. The steel material provides a solid foundation for the design and allows for intricate detailing.

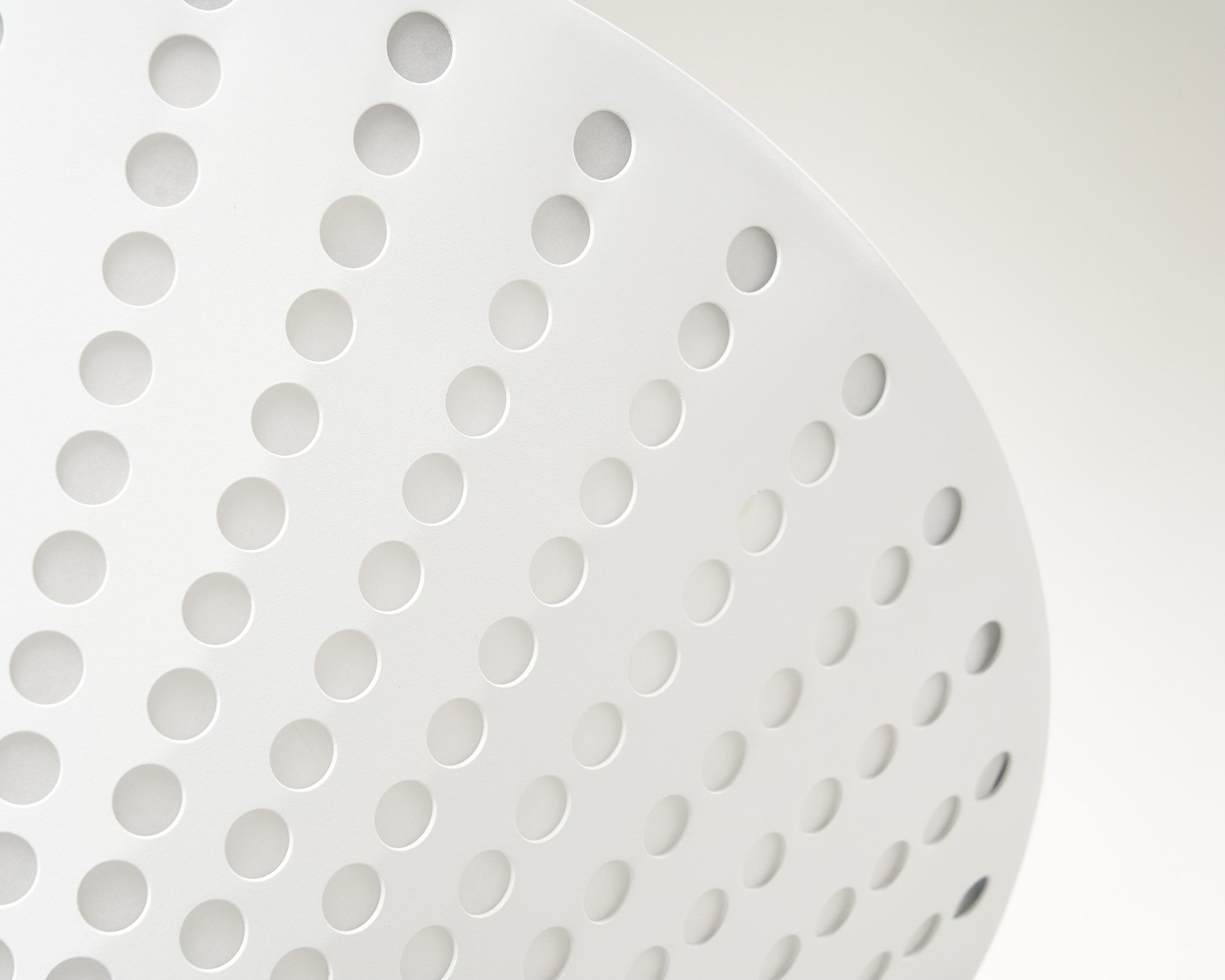

One of the defining characteristics of this pendant light is the presence of perforated holes. These holes are carefully placed across the surface of the cone shape to create a mesmerizing lighting effect. When illuminated, the light escapes through these perforations, casting intricate patterns and adding a sense of enchantment to the surrounding environment.

After the laser cutting process, the steel is hand-formed into the desired cone shape. Employing a combination of techniques, including the use of a press brake and hammer, to achieve the desired curvature and smoothness. Additionally, a 3D printed dolly is utilized to support and guide the shaping process, ensuring precise and consistent results.

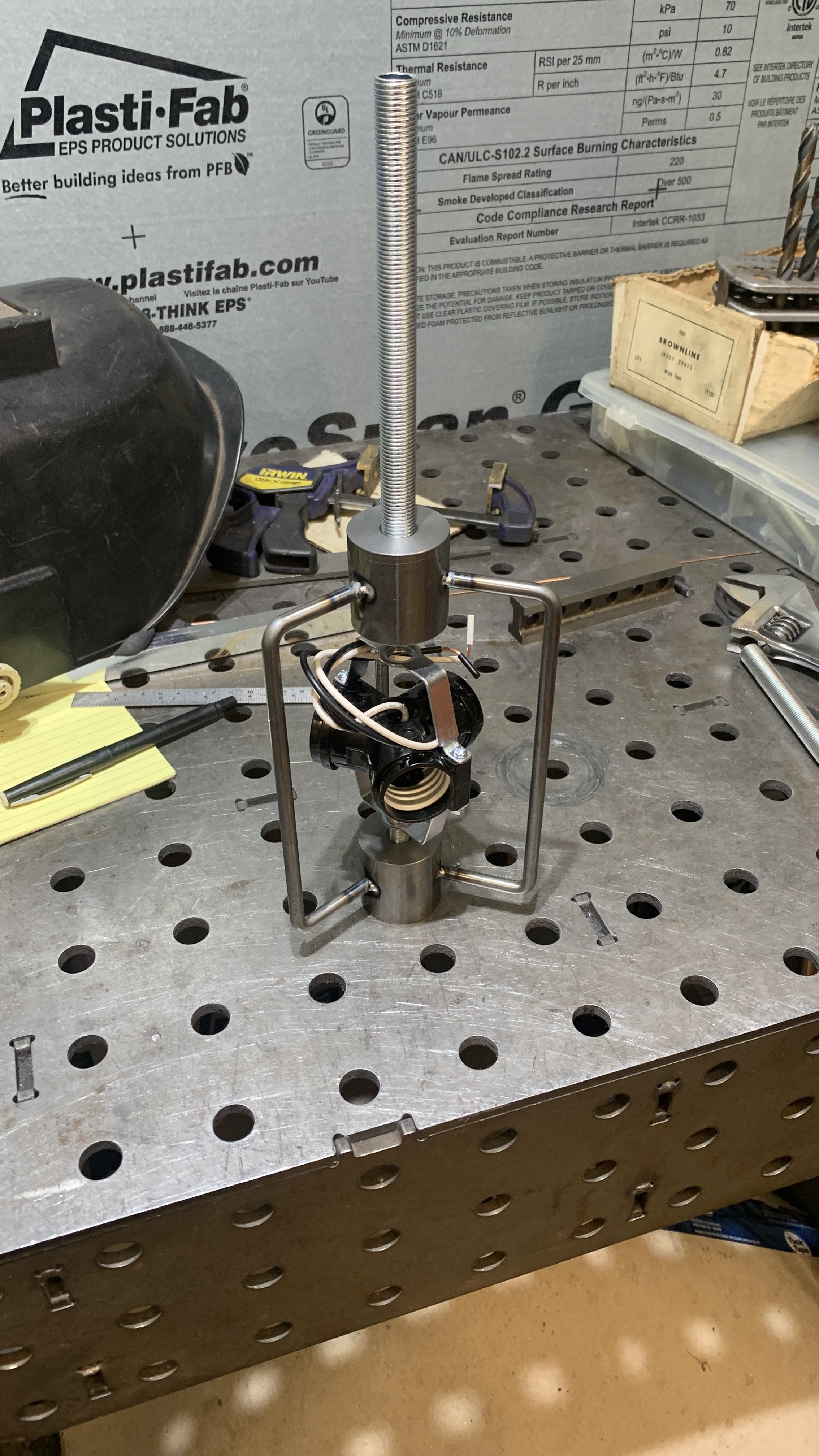

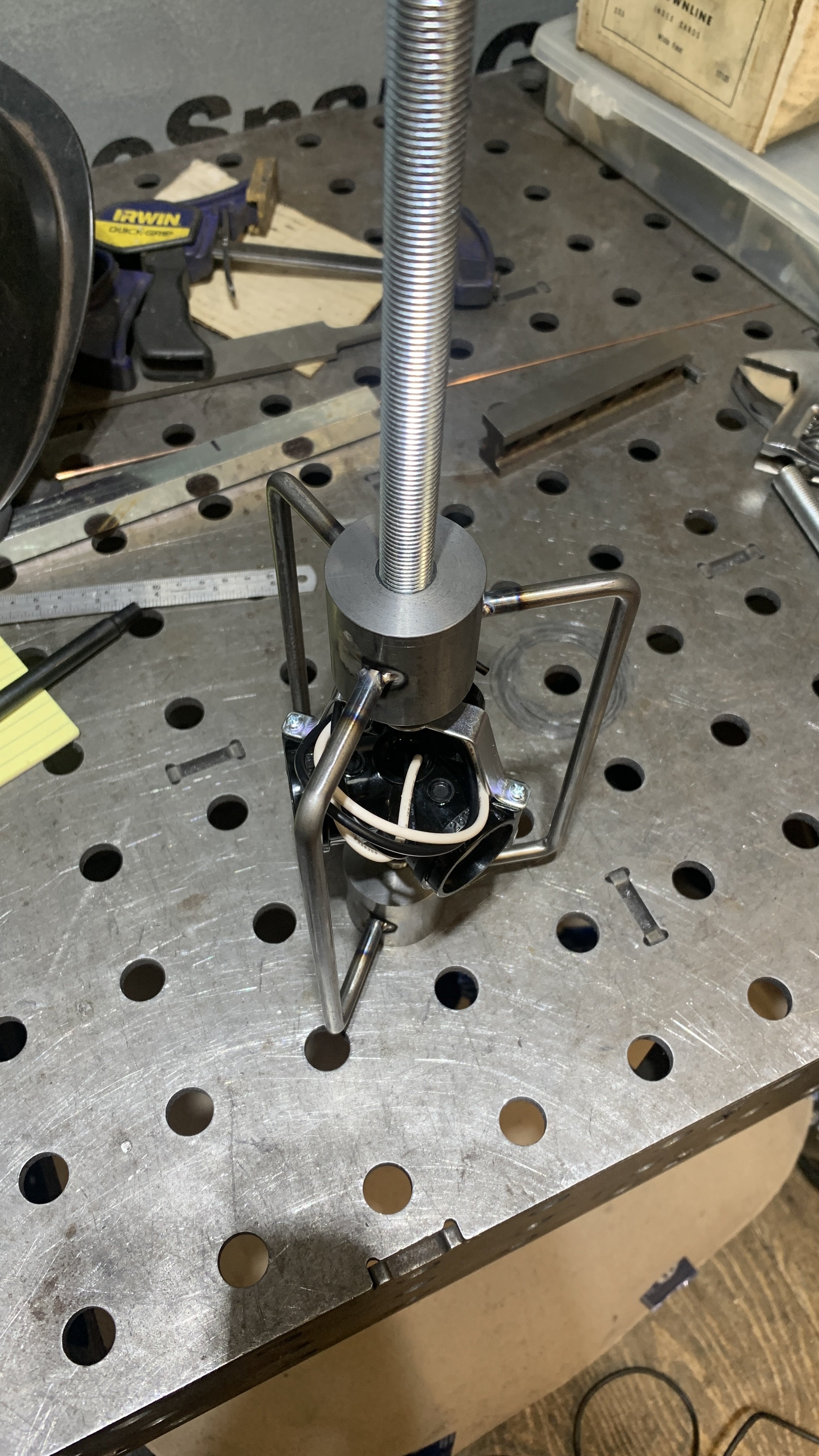

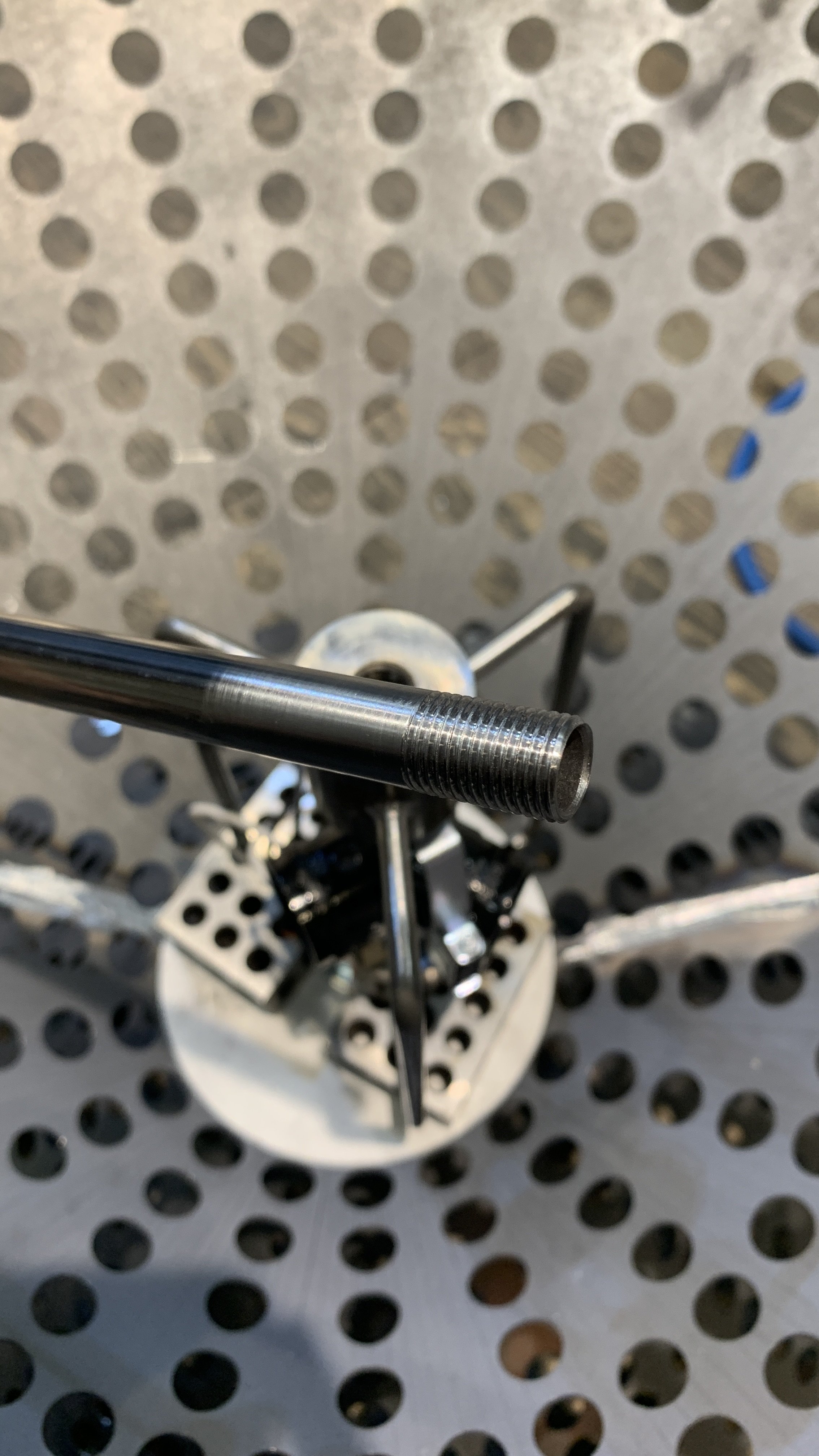

To ensure seamless installation and functionality, the pendant light incorporates CNC machined interior hardware. This hardware serves two essential purposes: hanging the fixture securely from the ceiling and providing mounting options for two or three tape light sockets. The precise machining ensures a snug fit and optimal stability, guaranteeing a safe and reliable lighting solution.

To enhance the aesthetic appeal and protect the steel surface, the pendant light is finished with a semi-gloss powder coat. This finish adds a subtle sheen to the steel and helps to prevent corrosion and wear over time. The semi-gloss appearance strikes a balance between elegance and practicality, allowing the pendant light to complement a variety of interior design styles.

Processes Used

-

CNC Lathe

-

3D Printing

-

MIG Welding