FDM 3D Printing

What is FDM 3D printing ?

FDM (Fused Deposition Modeling) 3D printers are a popular type of desktop 3D printer that use a filament of thermoplastic material, typically PLA or ABS, to create 3D objects layer by layer.

The printer works by heating the filament and extruding it through a nozzle onto a build plate or previously printed layer. As the filament cools and solidifies, it forms a solid object. The printer can create objects with a maximum size determined by the build volume of the printer.

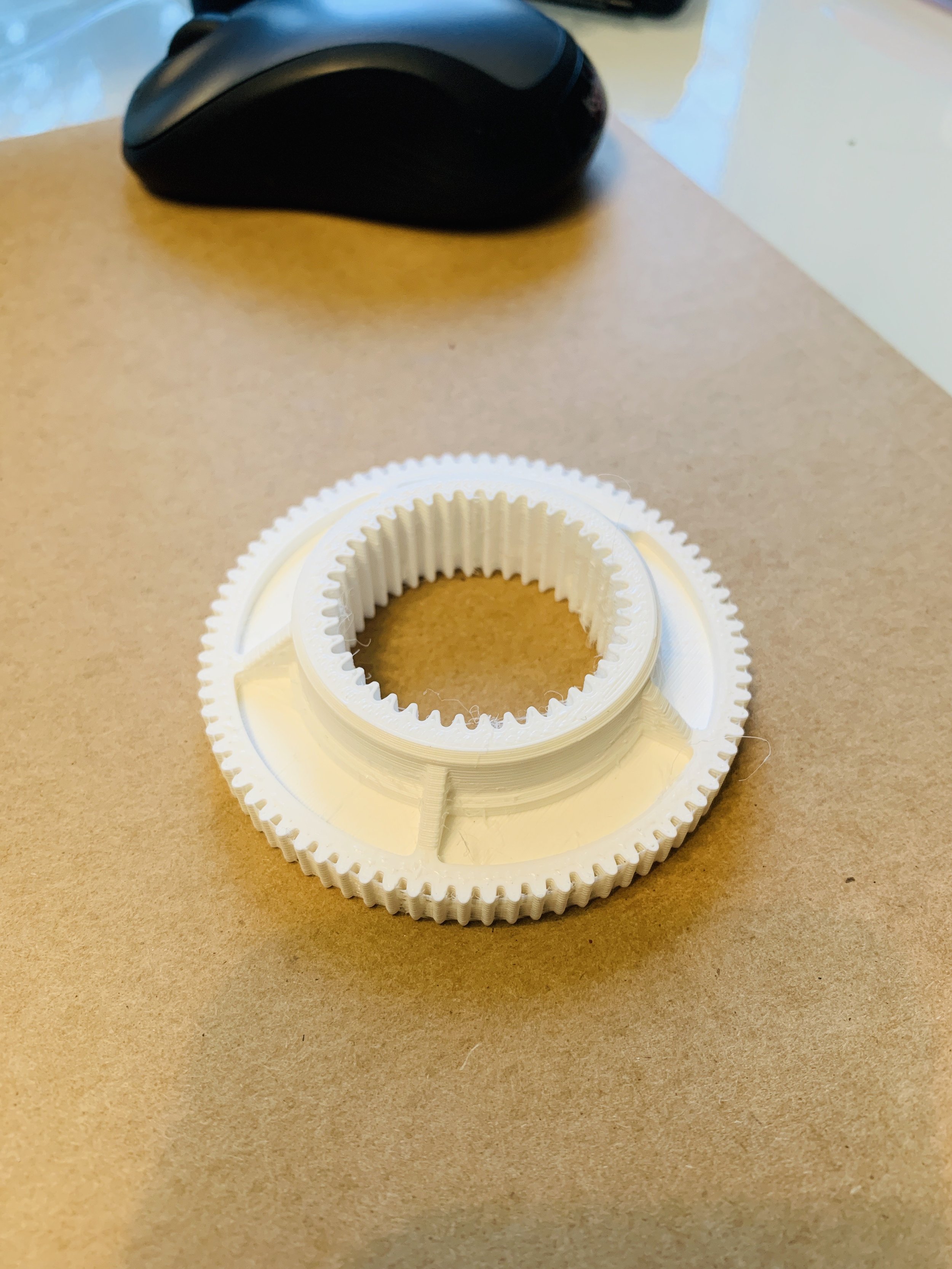

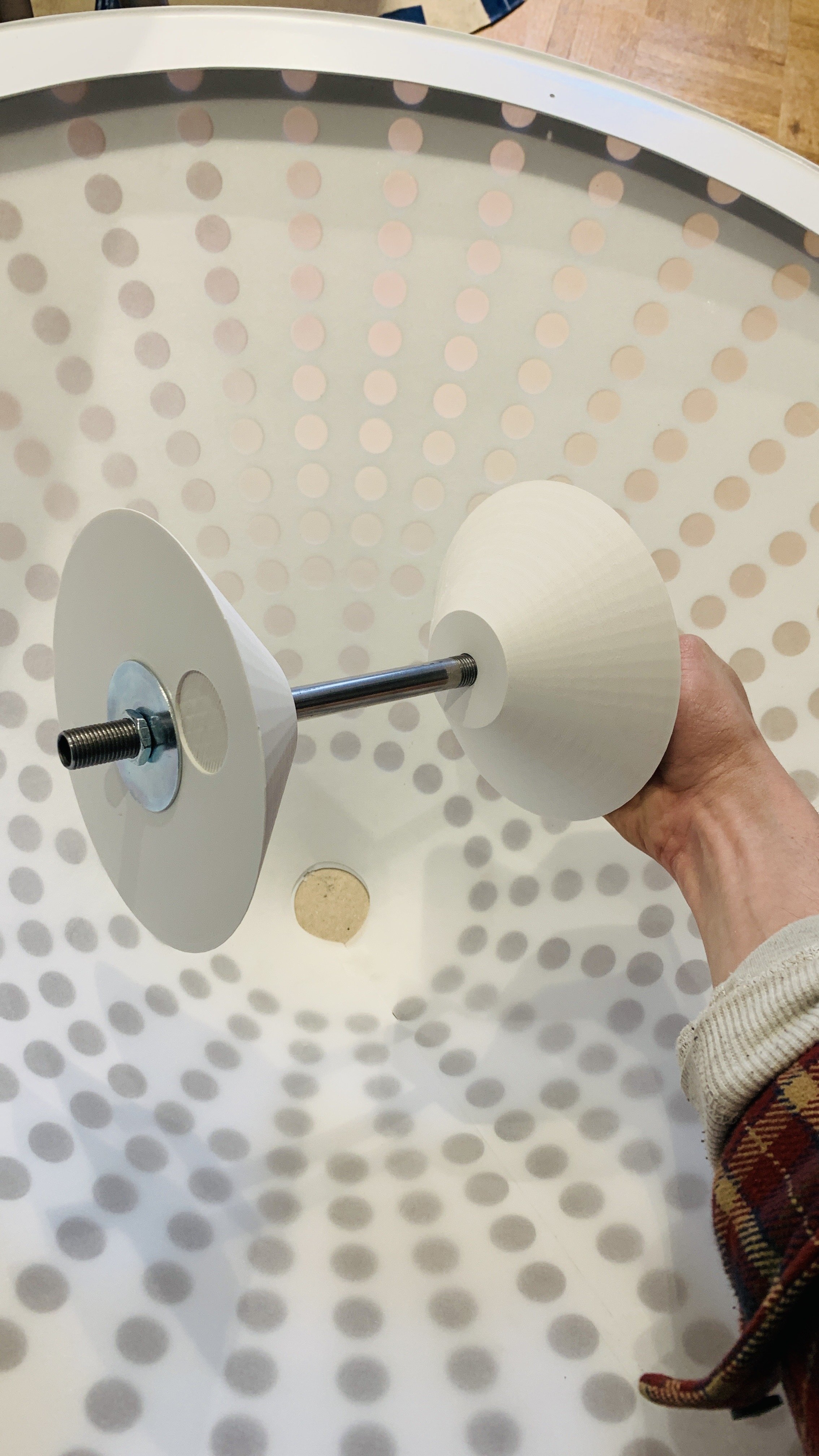

FDM 3D printers can create a wide variety of objects, including prototypes, toys, household items, art, and even functional parts for machinery. The objects can be simple or complex, and can have different colors and textures depending on the type of filament used.

One of the main advantages of FDM 3D printing is its affordability and accessibility, making it popular for hobbyists, makers, and small businesses. With the right skills and software, FDM 3D printers can create highly detailed and precise objects with a variety of shapes and sizes.

What size parts fit the printer ?

Our FDM printer can build parts up to

8.0 inches (203.2 mm) height,

8.0 inches (203.2 mm) width

8.0 inches (203.2 mm) depth.

Typical Materials

-

Polylactic Acid

-

Polyethylene Terephthalate Glycol

-

Acrylonitrile Styrene Acrylate

-

Acrylonitrile Butadiene Styrene