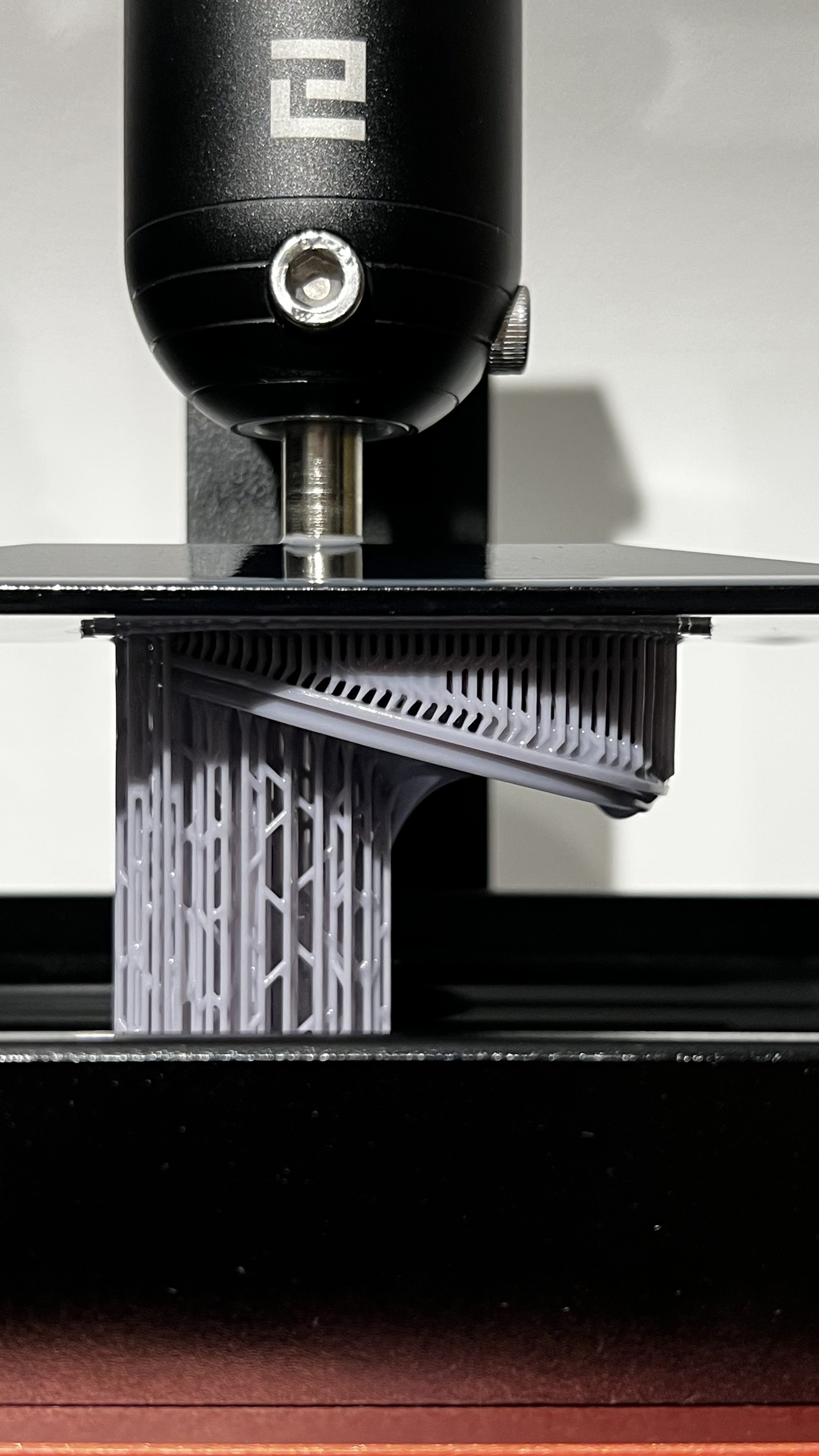

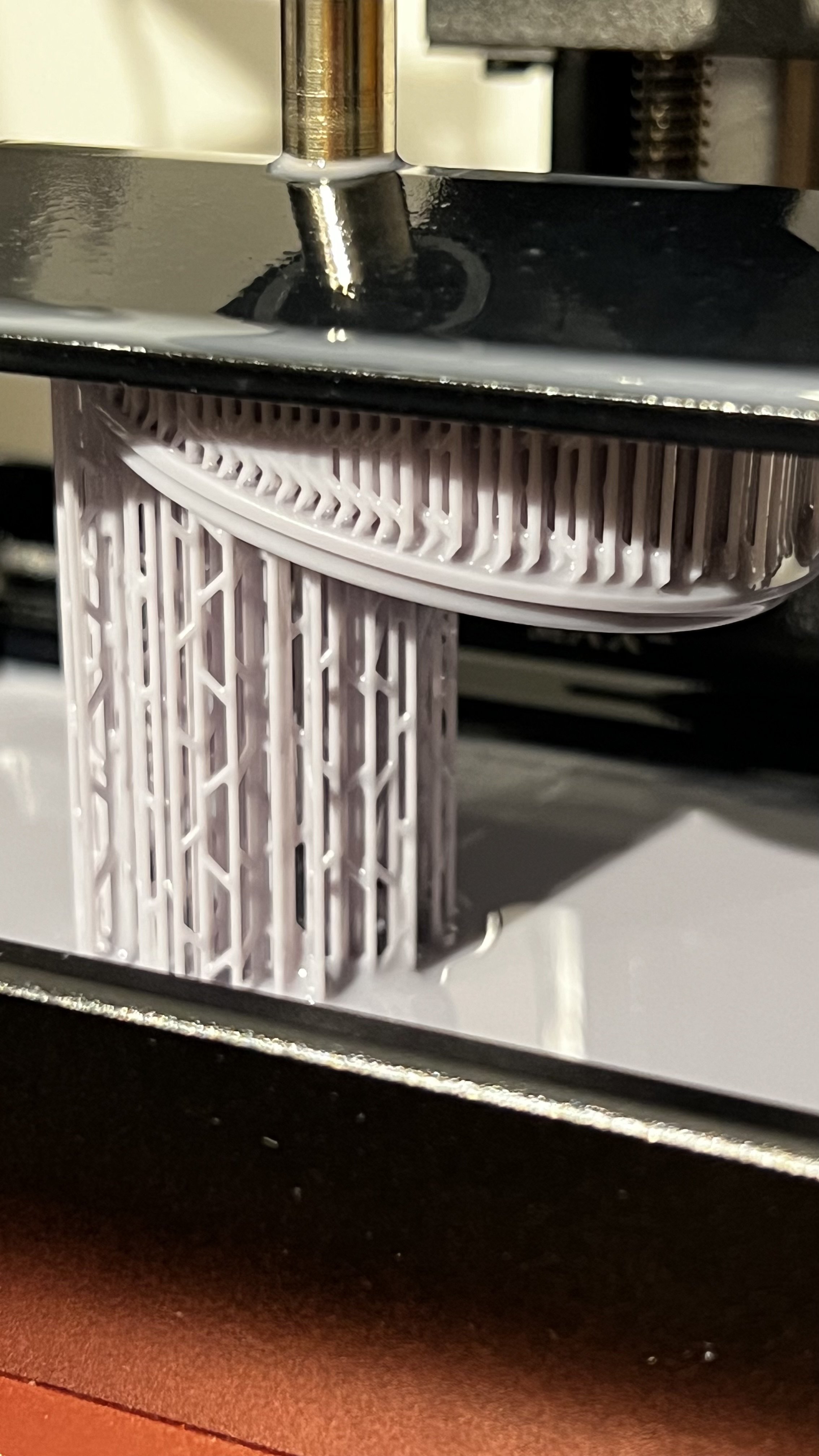

Resin 3D Printing

What is resin 3d printing ?

A resin 3D printer, also known as a stereolithography (SLA) printer, is a type of 3D printer that uses a liquid resin material to create 3D objects layer by layer. The resin is cured by a light source, usually a laser or an ultraviolet (UV) light, which solidifies the resin layer by layer, forming the final object.

Resin 3D printers offer high resolution and are capable of producing intricate details, making them ideal for creating small, intricate objects like jewelry, dental models, and figurines. They can also be used to create complex mechanical parts, such as gears, that require precise dimensions and smooth surfaces.

One of the advantages of resin 3D printing is that it can produce objects with a smooth, glossy finish and high levels of detail. However, the process can be time-consuming, and the materials used can be expensive. Additionally, the fumes emitted by the resin can be toxic, so it's important to use a well-ventilated workspace and wear appropriate protective equipment.

Overall, resin 3D printing is a powerful technology that offers great potential for creating detailed, complex objects with a high level of precision and accuracy.

What size parts fit the printer ?

Our resin 3D printer can build parts up to

6.88 inches (175 mm) height,

5.62 inches (143 mm) width

3.52 inches (89.6 mm) depth.

Typical Materials

-

High Res Gray

-

Bio Resin

-

ABS Like

-

Nylon Like