Plasma Cutting

What is plasma cutting?

A plasma cutter is a tool used to cut various materials, including metal, steel, and other conductive materials. It works by creating a high-temperature plasma arc, which is used to melt and cut through the material. The plasma cutter uses an electrical arc to ionize gas, typically compressed air, and then heats the ionized gas to a very high temperature, producing a plasma jet that can be directed onto the material being cut.

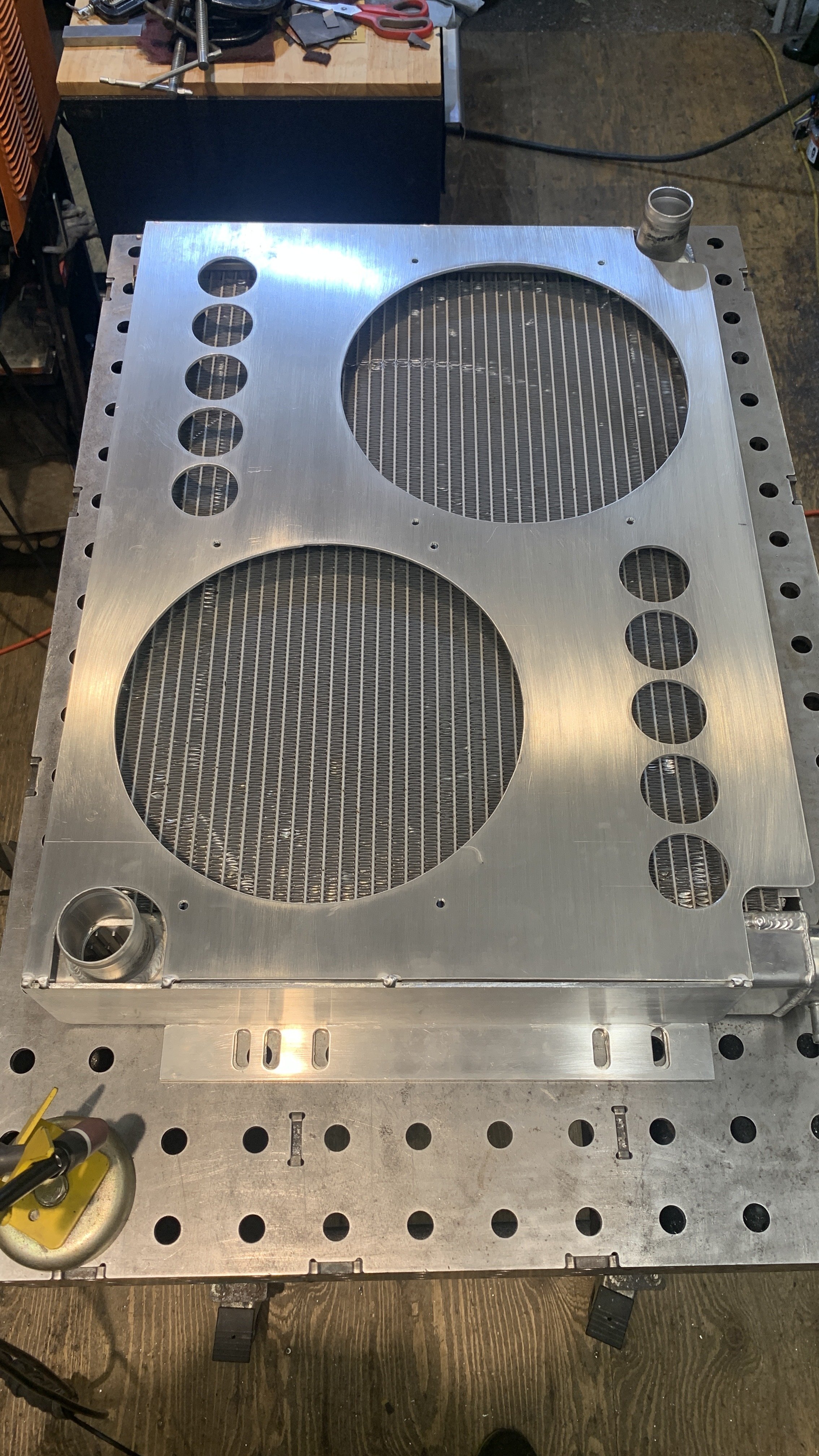

Plasma cutters are used in a wide range of applications, from industrial manufacturing to DIY projects. They are particularly useful for cutting through thick metal sheets quickly and accurately, making them an ideal choice for metal fabrication and welding applications.

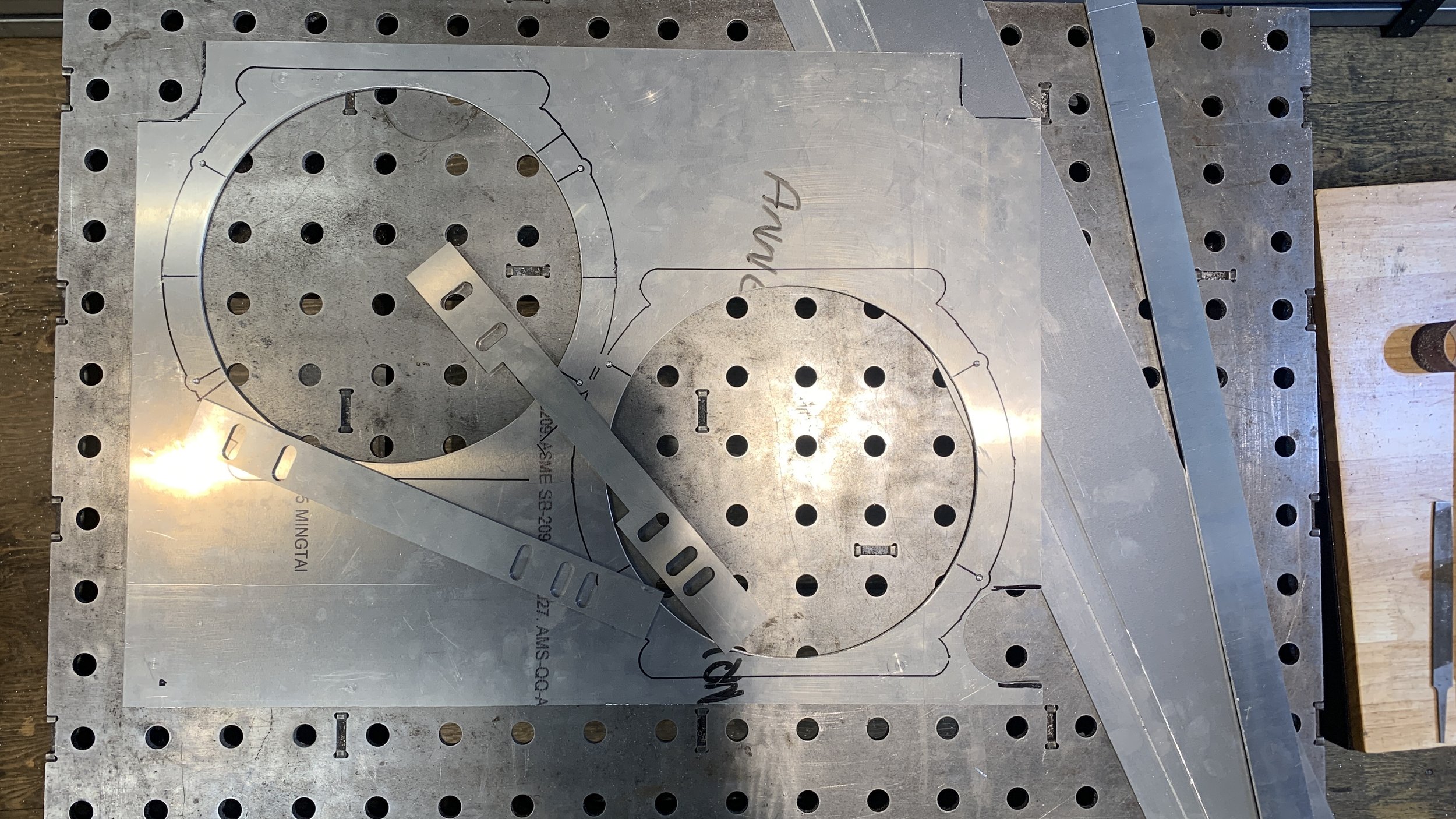

Some of the items that can be made using a plasma cutter include decorative metalwork, metal sculptures, machine parts, and custom metal signage. Plasma cutters can also be used to make intricate and detailed cuts, allowing for more precise designs and shapes to be created. They are commonly used in automotive and aerospace industries for creating parts and components with a high degree of accuracy.

Overall, plasma cutters are a versatile and efficient tool that can be used in a variety of applications, from small-scale DIY projects to large-scale industrial manufacturing.

Typical Materials

-

Aluminum

-

Steel

-

Stainless Steel

-

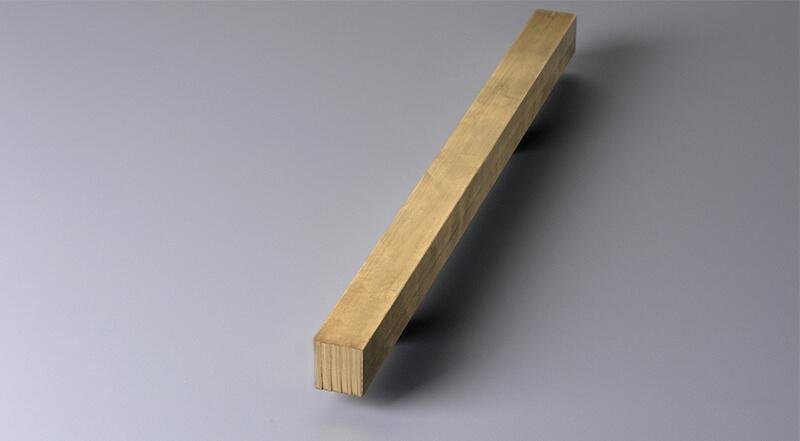

Brass