3 Axis CNC Mill

What is a 3 Axis CNC Mill ?

A CNC (Computer Numerical Control) 3-axis mill for metal is a specialized machine that uses computer-aided design (CAD) software to precisely control the movement of a cutting tool along three axes (X, Y, and Z) in order to remove material from a metal workpiece. The machine can be programmed to create intricate shapes and contours with high precision and accuracy, allowing for the creation of complex parts and components.

The CNC 3-axis mill can make a wide range of metal parts, including gears, engine components, brackets, and other mechanical parts. It is often used in industries such as aerospace, automotive, and medical device manufacturing, where precision and repeatability are essential.

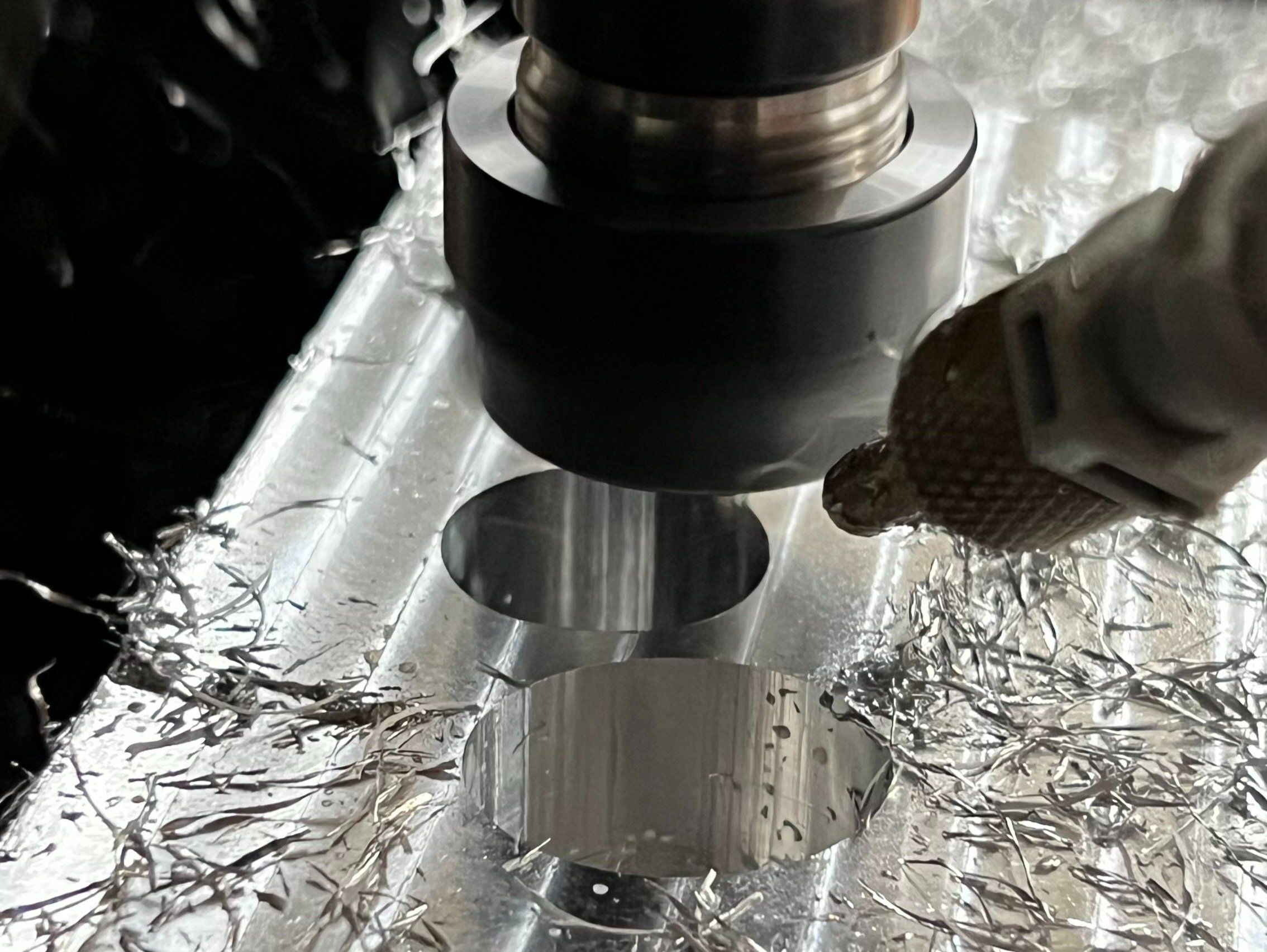

The machine works by first loading a metal workpiece onto a bed or table. The cutting tool is then brought into position and programmed to move along the three axes to remove material from the workpiece. The machine may also use coolant or lubricant to reduce heat and prevent the cutting tool from becoming dull or damaged.

In addition to metal, a CNC 3-axis mill can also be used to work with other materials such as plastics and composites, depending on the type of cutting tool and machining process used. Overall, the CNC 3-axis mill is a powerful tool for creating precise metal parts and components, and plays a critical role in many industries that require high-quality, custom-made products.

What size parts fit on the Mill ?

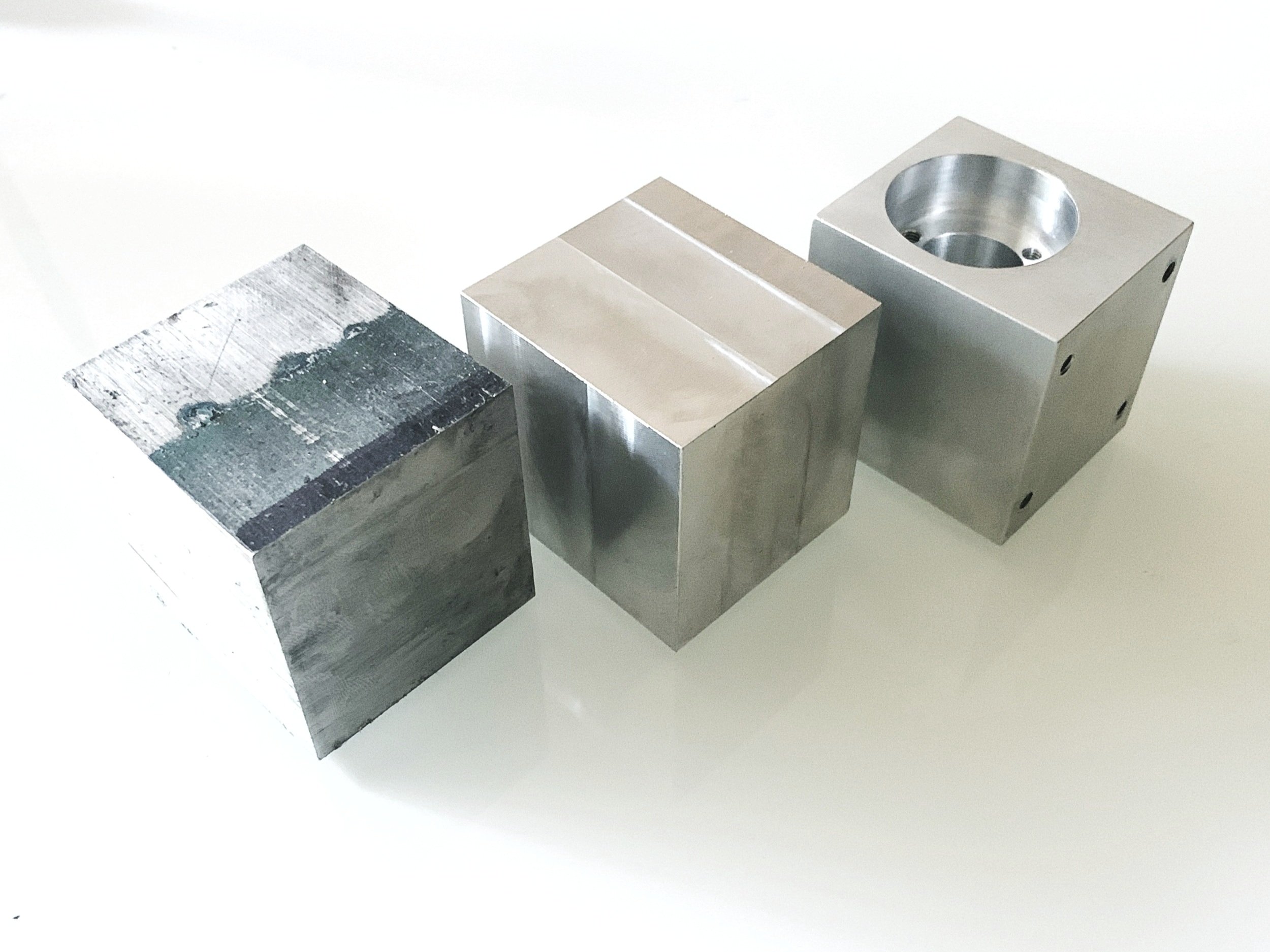

Our 3-axis CNC mill can effectively cut materials up to

9.0 inches (228.6 mm) height,

15 inches (381 mm) width

6.125 inches (155.575 mm) depth.

While the milling volume remains fixed, the size of parts that can be fixed on the bed is not limited to these dimensions. Larger parts can overhang the bed as long as the features that needs to be machined fall within the milling volume.

Typical Materials

-

Aluminum

-

Steel

-

Stainless Steel

-

Brass

-

Polymers (Plastics)